Some Known Incorrect Statements About Ldr Engines And Gearboxes Pretoria

Some Known Incorrect Statements About Ldr Engines And Gearboxes Pretoria

Blog Article

6 Simple Techniques For Ldr Engines And Gearboxes Pretoria

Table of ContentsThe Ultimate Guide To Ldr Engines And Gearboxes PretoriaFascination About Ldr Engines And Gearboxes PretoriaThe Ultimate Guide To Ldr Engines And Gearboxes PretoriaThe 9-Second Trick For Ldr Engines And Gearboxes PretoriaThe Greatest Guide To Ldr Engines And Gearboxes Pretoria

Before this test, the problem of the engine was unidentified. The only information provided to us from the previous owner was that the cylinder head was sent out to the factory for servicing. Cylinder number four exposed the piston top with heavy carbon accumulation on one half while the opposite side was clean.Disclosing this issue would certainly have been impossible if we have actually not had the ability to utilize the borescope to see the engine's interior problem. A lot can be found out about what is taking place in the combustion process by effectively checking out each spark plug. Checking out trigger plugs can also offer you an early indicator of a problem that might be just starting.

A black or ashy residue texture on the insulator suggests overly abundant air/fuel ratios (AFRs), while extremely light tan or white, raw insulators might direct to an AFR that is also lean - http://prsync.com/ldr-engines-and-gearboxes-pretoria/. Wet connects or oil on the plug can show a piston ring issue. Melted or missing electrodes, as well as harmed or ruined insulators, are noticeable indicators that something has gone seriously incorrect with the engine

The fighter engine experienced an over-boost failing with lean air/fuel conditions which inevitably led to catastrophic piston failing. The majority of failures are oil-related, but they can be caused by a number of problems consisting of age, thrust bearing failure from reduced oil pressure, or oil seal issues.

The Main Principles Of Ldr Engines And Gearboxes Pretoria

International things or dust ingestion (dusting) can create inlet blades to finish off or come to be damaged, specifically if an air filter isn't used. To test the problem of the turbocharger, get rid of the filter or inlet pipelines and examine the radial play of the input shaft by delicately relocate backward and forward.

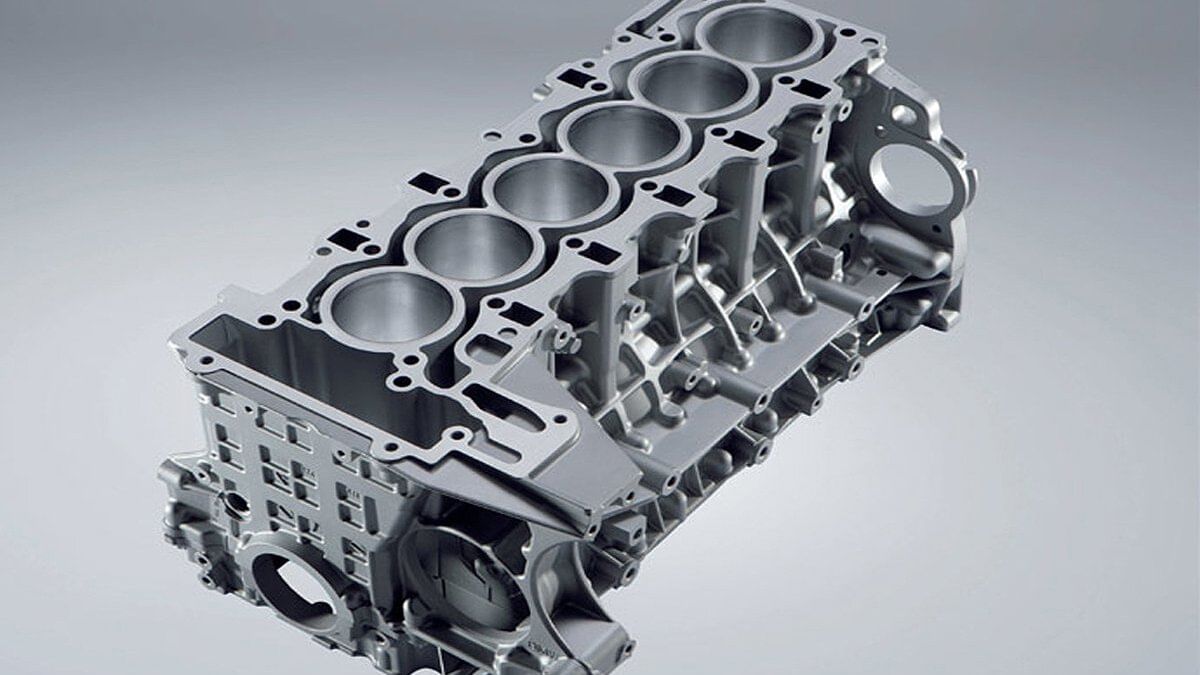

A compression test is commonly done prior to a leak-down test and is a very easy means to identify the inner health and wellness of your engine; a bulk of made use of engine stores will certainly utilize this screening approach to acquire info on an engine's condition, after that pass it on to their prospective purchasers.

A weak battery, rusted starter cord, or a warm starter can all trigger the engine to crank a lot more gradually, which can influence the examination results. Also air density and shutoff lash can impact the analyses. A cold engine will have less compression then a warm engine.

The Best Guide To Ldr Engines And Gearboxes Pretoria

The '98 Civic Type-R swap is a popular performance engine upgrade, and includes some differences from previous '96-'97 Type-R designs to make it a lot more appealing to customers. These include a 4-into-1 exhaust manifold and a machine-ported cyndrical tube head contrasted to the earlier models which were hand-ported at the factory. "When compression-testing this particular sort of engine, we anticipate it to hit a minimum of 210 psi, because of the nature of its high-compression develop," says Ankor.

A fast bump exposed cylinder No. 1 cranking out 155 psi, which Ankor points out is thought about truly healthy and balanced for this certain year and model engine."Sometimes you will certainly see the exact same kind of engine pressing 180 psi, however higher isn't always better. When the numbers check out high up on a used engine that would certainly suggest carbon accumulation on the piston crowns which provide an incorrect reading," he states.

All about Ldr Engines And Gearboxes Pretoria

We test our engines completely dry to make sure repeatable compression number results. Any kind of engine with worn-out piston rings checked damp will always reveal greater compression numbers versus a dry test.

We received this engine less than two weeks back from Japan so it's rather fresh and in great running problem (engines for sale) (https://www.figma.com/design/uV1df7i7TMvFA5geU68srl/Untitled?node-id=0-1&t=eAEgbfGa3tJ22ABp-1). When any kind of engine sits for a very long time, oil needs to flow though it to obtain appropriate compression measurements," he explains. Executing a leak-down test will certainly supply you a lot more comprehensive details regarding the mechanical problem of your engine compared to utilizing a compression tester

5 Simple Techniques For Ldr Engines And Gearboxes Pretoria

Apply the pressed air and modulate the knob to obtain a consistent analysis from both gauge deals with. Using the same amount of air stress on all cylinders, and pay attention thoroughly for sounds of escaping air. If you hear or really feel air escaping at the oil filler cap, you are losing compression with the rings or a scuffed cyndrical tube bore.

If air is heard near the throttle body/intake manifold, all indicators point towards the consumption valves. If air is getting away though the radiator tube, there's an excellent possibility the engine has a blown head gasket. We evaluated the condition of our L18 engine using a leak-down tester and were compensated with some unexpected results

Report this page